Mount Mills

Situation

A mile downstream from Bridge Street Mill in Witney, it was

built on a 14-acre site known as Mount Farm. It was located next

to the railway goods station so was conveniently placed for

receiving in raw materials and sending out finished goods.

Physical structure

Built by James Marriott in 1897-1900 to designs by J. Kirk and

Sons of Dewsbury. It was designed as a fully integrated modern

factory which combined and catered for all stages of blanket

production on one site. This was in contrast to many of the

earlier mills in Witney which had developed from fulling or

water-powered spinning establishments and where the weaving and

finishing processes tended to be fitted around these original

activities.

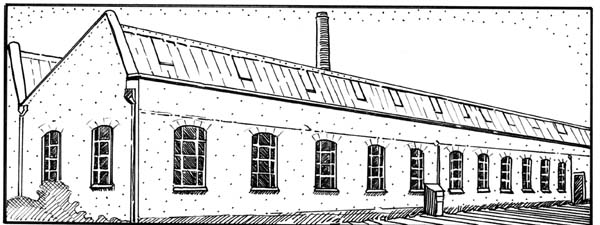

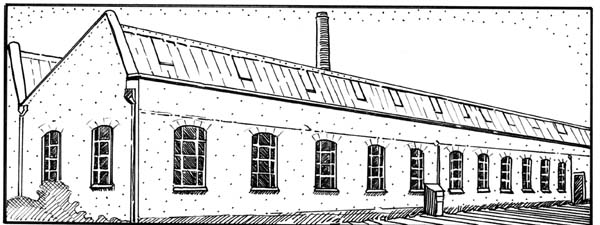

Drawing of the weaving sheds at Mount Mills.

Mount Mills was affected by enemy action in the Second World War

when the glazed roofs of the weaving sheds were damaged by bomb

blast and warp threads were severed by falling glass; workers

were sent home for the morning while repairs took place [3]. A

fire in 1953 seriously damaged the northern part of the mill,

which included the carding and spinning departments. It was

completely rebuilt and operational within six months; in the new

building there was no overhead line shafting as each item of

machinery now had its own electric motor, and modern ventilation

and fluorescent light fittings were installed. A decision to

consolidate production at Witney Mill lead to Mount Mills being

vacated in 1985, sold in 1989, and demolished shortly after [4].

Owners

James Marriott (1827 - 1904) had the factory built when he

decided to form a new textile company towards the end of the

Victorian period. It opened for business in 1901 although

blanket production had started the year before. The Marriott's

were a long established blanket making family, though by the

19th century they were also connected with farming, dyeing and

coal selling [5].

On completion of the new mill, Marriott's had ownership and

control of a 'new and spacious blanket mill in which was laid

down the most complete and up to date plant' [6].

Marriott's merged with the Charles Early and Company in 1960 to

form Charles Early and Marriott (Witney) Ltd.

What was the site used for?

All stages of blanket production were carried out here: the site

was planned and laid out for power weaving and had separate

departments for carding, spinning, warping and warehousing. Rows

of tentering racks for drying, can also be clearly seen on the

1899 Ordnance Survey map of Mount Mills. The business at this

early stage was concentrated on wholesale rather than retail.

It was here during the 1960s that Fiberweaving technology was

introduced into Witney blanket making, revolutionising blanket

production. The Fiberweaving machines made not just blankets but

also floor coverings and industrial felts. Electric blankets

were also made by this method at Mount Mills.

Clare Sumner

|