Raising or 'rowing'

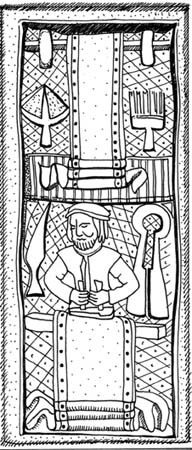

Drawing of a Medieval bench end from Somerset showing a cloth

worker with finishing tools including shears, knife and teasel

rack. The rolls of cloth have holes in the edges made by

tenterhooks.

Raising the nap on the woollen cloth was the next step to

producing a finished product; in Witney this was also known as

'rowing'. It involved brushing the surface of the cloth all over

to remove any imperfections and give it a uniform appearance.

For centuries, this was done by brushing the cloth with the

dried heads of the teasel plant, a type of thistle head which

has many flexible, barbed spikes that effectively brush out wool

fibres without being so rigid as to tear the fabric. Several

teasels were set together into a wooden handle - these tools

were known as cards. Wooden paddles set with wire teeth were

also used for nap raising [1]. Again it was often the tuckers

who would carry this out on behalf of the weavers. They also

sheared off the nap with scissors or shears to make the cloth

smooth.

Apart from fulling stocks, rowing was one of the first processes

to be mechanised in the Witney blanket industry. The Witney

Blanket Weavers' Company purchased a horse powered 'rowing

machine' or gig mill in 1782 for the use of its members. One of

the entries in the accounts lists 'Ale, for getting the Horse

from under the Mill wheel'! [2]. The machine was used until

1818, when it was sold because the number of independent master

weavers was declining due to the rise of the larger companies.

Clare Sumner

|